Commissioning process

Stained and Leaded Glass Skylight Project Initiation

To start a visual dialogue and glass commissioning process we often ask our clients some business-related questions and to send us examples of work they’ve seen and liked. It helps us to identify the client’s goals, objectives, style preferences, and priorities. Project expectations are discussed, architectural plans reviewed and a timeline is defined. As many of our projects are built in into building we would like to be involved in the early stage of the project development such as planning or structural framing. Opening construction and preparation, lighting, trims and other important details concerning leaded glass skylight integration into building are discussed at this stage

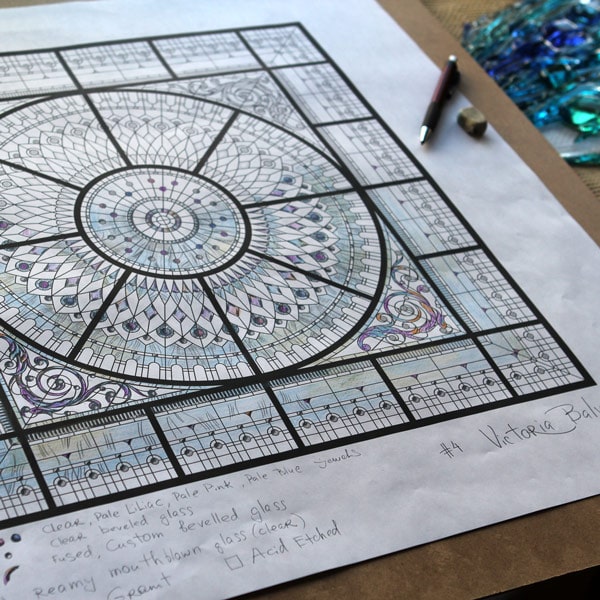

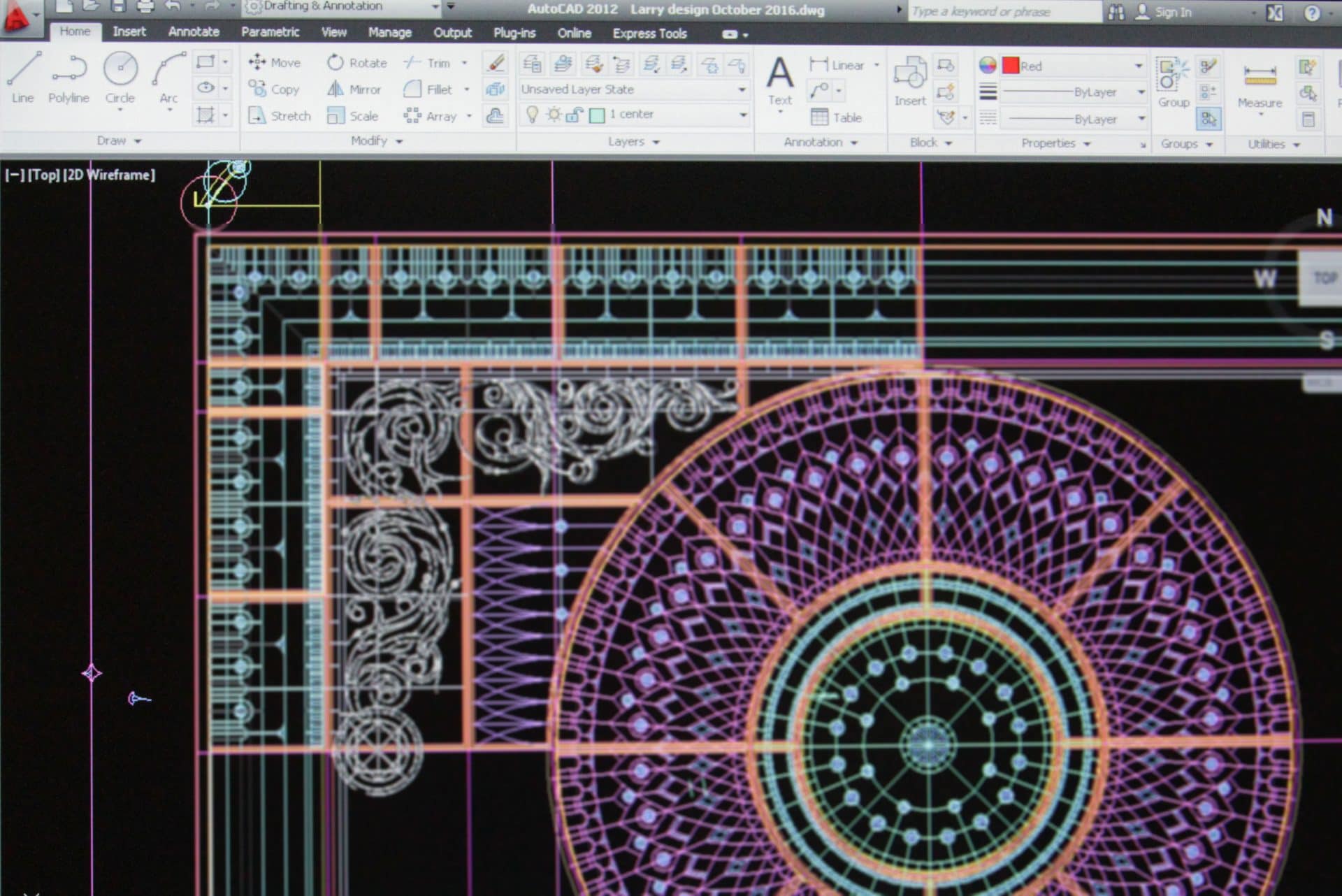

Design development and Approval

All stained and leaded glass domes and skylights are designed using AutoCAD in a scale 1 to 1. Presented sketches of leaded glass dome designs are a close representation of the finished piece. Few design variants of the leaded glass dome are offered to the Client with the possibility of a few minor revisions of the selected leaded glass skylight design. The artist reserves the right to improvise and adjust the leaded glass dome or skylight design according to the Client’s grounds. Technical and artistic aspects are integrated to build a unique site-specific piece of art.

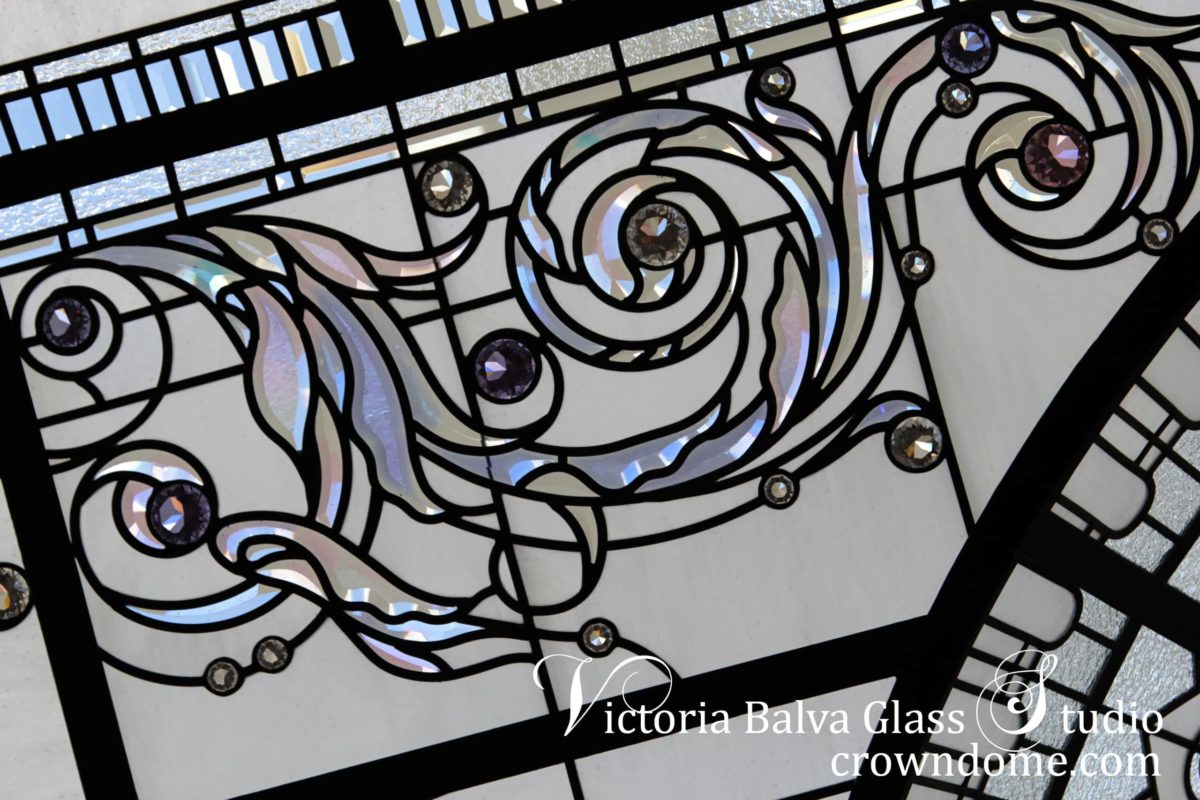

Leaded Glass Skylight Glass Selection

Unique combinations of textured art glass are used for leaded glass dome design to completely hide an unpleasant for a viewer structural elements such as beams, supporting columns, light fixtures, lightbox, access doors from the attic and etc. Not only technical elements are considered but also the artistic value of the stained glass dome may significantly be increased with the right selection of glass set.

Steel Frame Fabrication

All stained and leaded glass skylights and domes frames are fabricated in the studio with a high level of accuracy and precision. The metal frame is an important part of the leaded glass dome system. It supports leaded glass panels and also should be perceived as an integral element with the glass dome design. To avoid the formation of dark shadows by metal tee bars, all steel frames have a complex 2 color finish

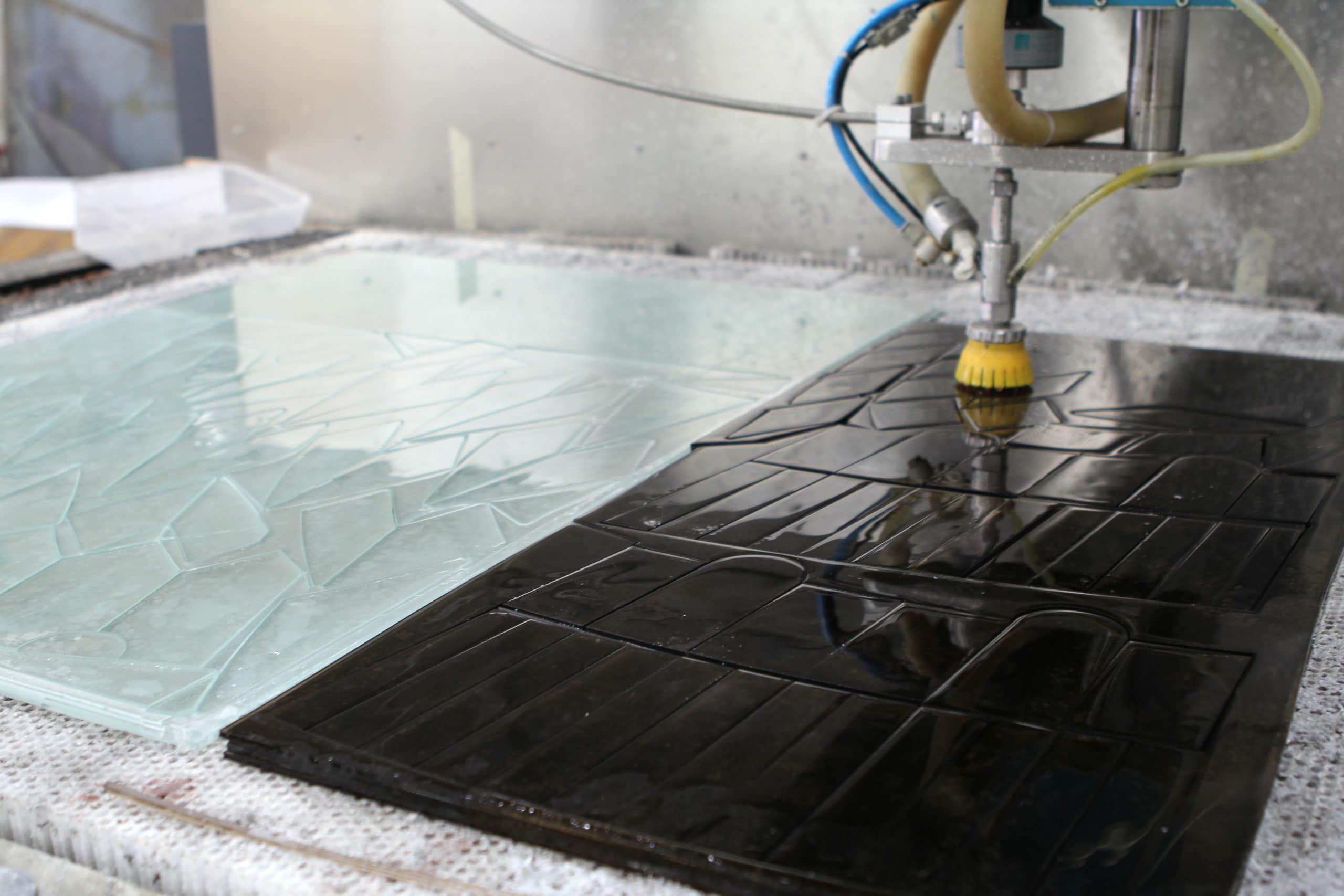

Templates and 3D Dome Molds

Stained glass domes templates and 3D molds are fabricated using a water jet precise cutting technology which allows building perfect spherical surfaces for glass assembling

Glass Dome Panels Fabrication

After the design is approved by the Client materials are ordered, shop drawings are developed, water jet machine programmed to cut glass parts. The average dome is made of 3 000 - 10 000 glass pieces and 9 000 - 30 000 leaded came parts. CNC cutting allows keeping consistency and high quality of all parts which intensify the glass dome appearance after installation. Water jet technology also helps to cut metal, glass and stone parts that are not possible to cut by hand

Stained Glass Dome Reinforcement

Victoria Balva Glass Studio has developed a unique technique of stained and leaded glass panels reinforcement by steel rebars to prevent panels from sagging and prolong stained and leaded glass dome lifetime. These bars are welded to the top of the glass panels and are not visible from below

Installation and Delivery

After stained and leaded glass dome is fabricated at the studio, the large frame is cut in pieces for delivery, packed and reassembled using TIG welding technology (sparkless) at the construction site. Leaded glass dome installation can be divided into 2 sessions that allow installing moldings, lighting, and painting after leaded glass dome frame installation. Leaded glass dome panels can be installed at the end of the construction process and should be protected from dust until full completion of the construction process.

National & International Orders

International Orders

At the end of leaded glass dome production frame and glass panels are packed and crated. The freight company ships the crates to the Client's location. The leaded glass skylight may be installed by a local subcontractor or by Victoria Balva Glass Studio's installation team on the Client's request

Technical aspects to consider

Opening Preparation

It is recommended to have an area above the leaded glass dome accessible from the attic or another room for an easy access to the light fixtures and also to provide a stress-free decorative glass skylight maintenance. Ideally, a deck should be built around the opening to allow a maintenance personal to access all leaded glass skylight panels without setting up scaffolds. The walking area of the deck around the opening should be approximately 2 feet.

Ventilation

Air returned duct vents should be installed above the stained glass dome or skylight for proper ventilation. Hot air is trapped above the stained glass dome and may damage the stained glass dome panels over long periods of time if not installed. A gap between decorative trims and stained glass dome frame should be left to equalize air pressure.

Light

To achieve balanced artificial lighting during night time the leaded glass dome should be lit by reflected from the ceiling and walls light. The light source should not be installed in the immediate proximity to leaded glass dome panels. The color rendering index (CRI) is a quantitative measure of the ability of a light source to reproduce the colors of various objects faithfully in comparison with an ideal or natural light source. Light sources with a high CRI are desirable in color-critical applications such as stained glass domes and skylights installations

Request a quote

LIKE OUR CREATIVE PROJECTS?

Let's start a new project together!

2133 Royal Windsor Drive, Unit 35, Mississauga, Ontario L5J 4L6

© 2000 - 2020 Victoria Balva Glass Studio / Artistic Line Studio. Unauthorized use and/or duplication of this material without express and written permission from this website's author is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to Victoria Balva and www.crowndome.com with appropriate and specific direction to the original content